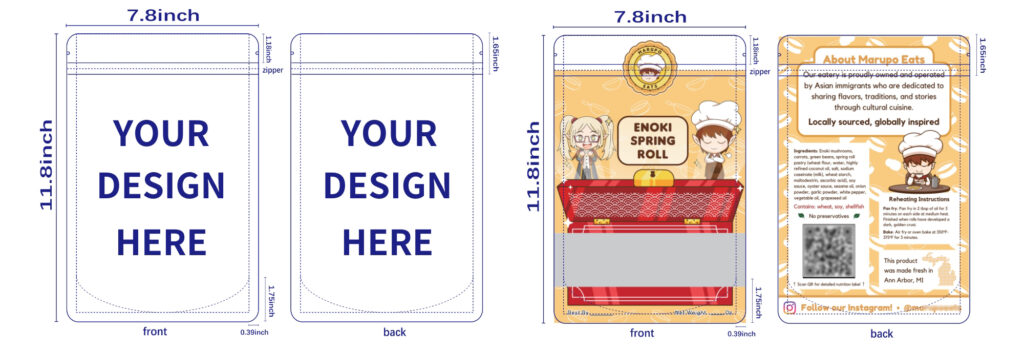

Stand Up Pouch 7.8x11.8x3.5 incch (20x30x9cm)

$338.09

Sales Price

Digital Printing

MOPP+PE

Matt Surface

7.8x11.8x3.5 inch / 20x30x9cm

Printing Way

Material

Surface

Size

CUTSTOM DESING

FAST DELIVERY

QUALITY ASSURANCE

OEM FACTORY

ECO MATERIAL

WATER RESISTANT

FOOD GRADE

CYCLIK UTILIZATION

AFTER SERVICE

-

Stand Up Pouch-7.8 x 11.8 x 3.5" (with window design)

7.8×11.8×3.5inch/500pcs(with window)

$338.09 Add to Cart -

Stand Up Pouch-7.8 x 11.8 x 3.5" (with window design)

7.8×11.8×3.5inch/1000pcs(with window)

$575.16 Add to Cart -

Stand Up Pouch-7.8 x 11.8 x 3.5" (with window design)

7.8×11.8×3.5inch/2000pcs(with window)

$1,041.63 Add to Cart

Size Template

Please check below carefully before you make confimation to us.if you have any further question,please contact our sales directy.

1、Please check and confirm the artwork, scan and test barcode/QR code if have.

2、Normally, offset within 0.3mm/0.11inch is allowable in cutting.

3、Color difference statement

(1) Regarding the color difference between displays and printed products:

Displays are composed of combinations of red. green, and blue light to create various colors, and different displays or the same display under different lighting conditions can exhibit significant color differences. Digital printing. on the other hand, utilizes CMYK ink to create colors, which has a lower color rendering capability compared to the combination of red, green, and blue light. Printed colors can not be based on the colors displayed on screens or printed copies; each screen and printer produces different colors. Please refer to the CMYK values and compare them with the print color chart.

We rejects the use of “I think,” “feel,” or “my screen color is correct” as the reference standard for product inspection. Our company uses Apple’s tablet display as the reference for print colors, but please consider the production time , storage method , and lighting environment when referencing colors for different batches.

(2)Regarding the color difference within the same batch:

Due to the fluctuations in digital printing machines, there may be slight color differences among prints within the same batch.

(3) Regarding the color difference between different batches with the same design content:

We ensures to use the same brand and model of printing materials, but due to the inherent deviations in each batch of raw materials and the impact of seasonal environments on printing machines, there may be some color differences between different batches of prints, which is a normal phenomenon.

(4) If surface finishing is matte lamination, the printing color will have more red looking, however, if go with glossy lamination, printing color comes out more darker.

(5) We uses the international standard color HP Indigo Press digital printing equipment, and a color deviation value of around 5%-10% is within the industry’s normal range.

4、How to minimize color differences?

(1) Please use professional software, such as Adobe CS suite, to complete your packaging design.

(2) Before designing, check the color settings of your design software to ensure that they are correctly configured.

(3) Avoid using colors that produce obvious color differences, such as blue-purple and brown.When designing gray colors, use single black instead of three-color gray to avoid unstable colors that are sensitive to printing, which can cause deviations each time they are printed; therefore, the same batch of products may have several different colors.

5、Simulated spot color

We use HP Indigo Press digital printing equipment with CMYK four-color ink/CMYKovg seven-color ink to accurately reproduce the effect of spot colors as much as possible. Since spot colors Usually can not be fully matched by CMYK mixing, simulating spot colors requires adjusting CMYK color values and printing techniques to approach the target spot color. Due to variations and limitations in the actual printing process, simulating spot colors may not always reproduce the target spot color accurately, allowing for a color difference of approximately 5%-10%.